|

Main Processing Technology |

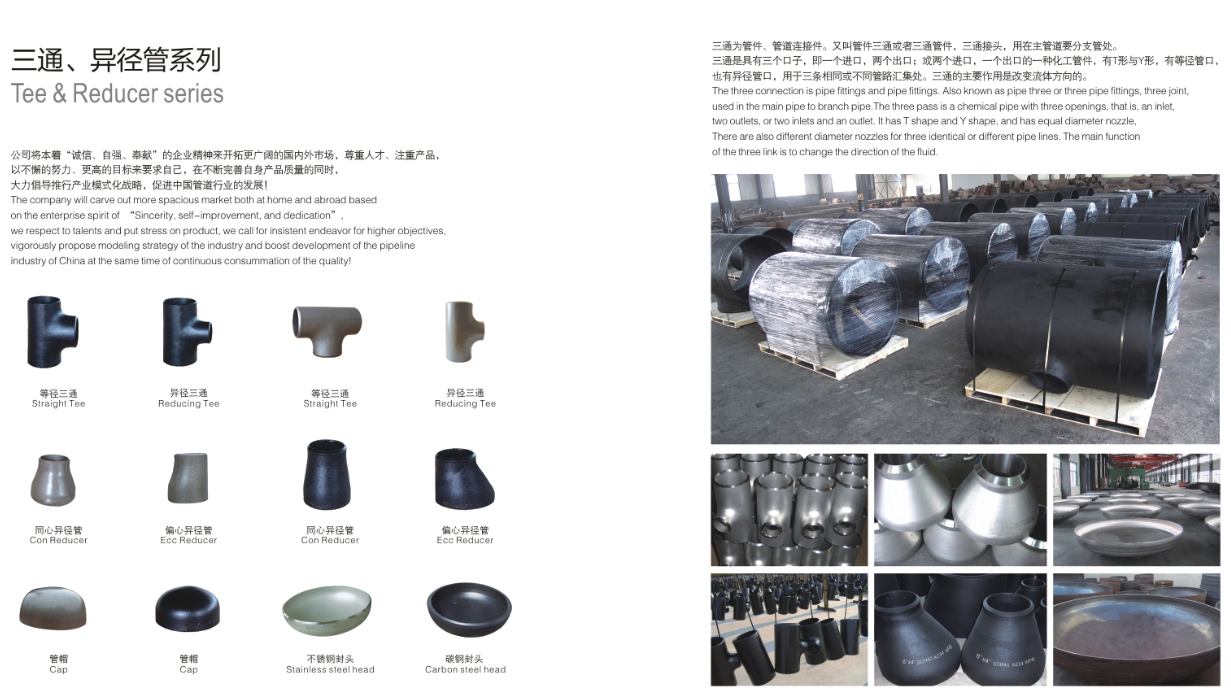

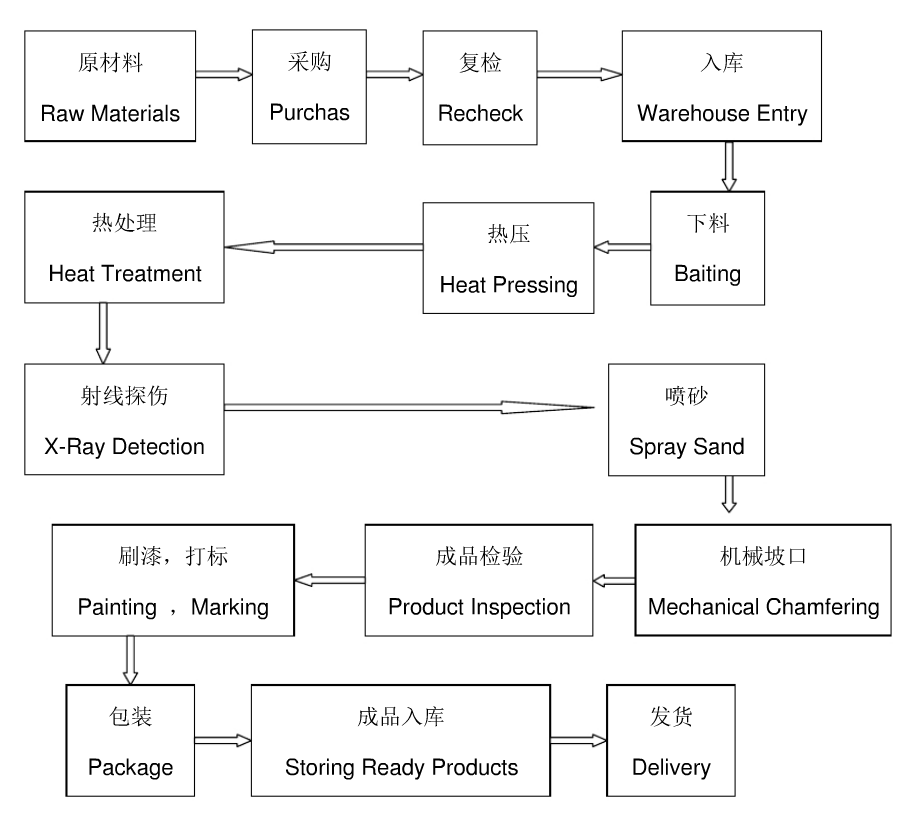

Raw Materials Into The Factory → Billet Cutting → Reel Pipe (Only In Seamed Pipe Fittings) → Welding (Only In Seamed Pipe Fittings) → Heating → Moul Ding → Heat Treatment → Machined Groove → Surface Treatment → Finished Product Inspection → Marking Protection → Put In Stock (Note: there is a pickling passivation process after stainless steel products groove processing) |

||||||||||||||||||

|

Size |

1/2"-120" |

||||||||||||||||||

|

Standard |

|

||||||||||||||||||

|

Wall Thickness |

SCH5, SCH10, SCH20, SCH30, SCHSTD, SCH40, SCH60 SCHXS, SCH80, SCH100, SCH120, SCH140, SCH160, SCHXXS |

||||||||||||||||||

|

Color |

Black, Yellow, Blue, Red. etc as client requirment. |

||||||||||||||||||

|

Surface Coating |

Rust-proof oil; Black; Galvanized; Polyethylene Coating; Epoxy Coating, etc |

||||||||||||||||||

|

Marking |

Marker permanent |

||||||||||||||||||

|

Package |

Ply-Wooden Case for small size Pallet for big size |

||||||||||||||||||

|

Certificate |

BV ISO9000,CRN,CE |

||||||||||||||||||

|

The Third Party Inspection |

BV,SGS,LOIYD,TUV,and other party alloyed by clients |

||||||||||||||||||

|

Brand |

TSZHONGRAN |

||||||||||||||||||

|

Min Order |

1PCS |

||||||||||||||||||

|

Payment Terms |

T/T, 100% LC AT SIGHT, 100% LC 30 OR 60DAYS AFTER BL OF DATE, |

||||||||||||||||||

|

Delivery Time |

7-30days according to acutal order. |

||||||||||||||||||

|

Delivery Port |

TIANJIN, QINGDAO,SHANGHAI, NINGBO, SHENZHEN, |

||||||||||||||||||

|

Delivery Ability |

3000TONS/MONTH |

||||||||||||||||||

|

Applicating |

Paper-marking, Oil and natural gas pipeline, Boiler and heat exchanger, Smelting,Water conservancy, Electric power, Chemical, Pharmaceuticals etc |

||||||||||||||||||

|

Main Equipment and Installation |

1:2500T press (mainly used for die forming) 2:500T Press (Mainly Used for Molding) 3:315T Press (Mainly Used for Molding) 4:150T Press (Mainly Used for Molding) 5: 2 coal-fired heating furnaces 6: 1 oil-fired heating furnace 7: 1 pipe blanking machine 8: Machining equipment: lathe C630, two lathes CW6163C, one lathe CR61100A, one milling machine a6232A 9: Heat treatment: 1 car-type oil-fired heat treatment furnace, effective heating area of 8 M2 car-type box resistance furnace RT9-80*1500*60, the highest furnace temperature 1200℃ 10: Sandblasting equipment 2 sets 11:One set of air compressor and one set of liquid cooling pool 12: 2.4m reeling machine 13:14 Argon Arc Welding and Handheld Welding Machines 14: 2 welding rod drying equipment 15:260 sets of mould tools for different diameter pipe 16: One stainless steel pickling tank 17: A manual grinder (for large-caliber groove treatment) 18: Two plasma cutting machines |

|

一.Acceptance and Acceptance of Raw Materials 1. Raw materials shall meet the requirements of relevant standards and technical specifications. 2. There should be no oil pollution on the surface of raw materials. Excessive rust corrosion and obvious dent defects, low melting point metal pollution, etc. 3. Check the quality certificate, furnace number, batch number and specifications of raw materials, manufacturers and implementation standards. 4. Mechanical rust removal of raw materials with wire brushes to meet the requirements of non-destructive testing. 5. Dimension testing of raw materials (length, diameter, thickness and unevenness of steel tubes). 6. After entering the factory, the steel pipe should be re-inspected by ultrasonic wave. Grade I is qualified. 7. Physical and chemical testing, chemical element analysis, mechanical properties and hardness testing of steel pipe or steel plate according to furnace batch number and specification. The test results should meet the requirements of relevant standards. 8. Number registration in accordance with factory regulations after reexamination 二. Manufacturing process 1. Material selection and blanking, according to the design requirements of different diameter pipe, select appropriate steel plate (rolled and welded into cylinder) or steel pipe, and use cutting blanking to clean up iron oxide and gas cutting spatter residues on pipe material. The furnace, batch number and pipe fittings specifications, engineering name and number of raw materials are clearly identified. 2. Compression Forming of Variable Diameter Pipe (1) Operators should learn relevant process documents and be familiar with the operation methods and process of equipment, and be prepared for all kinds of appliances needed in the process of work. (2) Furnace charging heating: The reducer blank is loaded into the natural gas heat treatment furnace, and the bottom is separated from the furnace by the horn to ensure the distance between the different diameter pipes is ≥200mm, and the heating rate above 400°C is ≤200°C/h. (3) Heating the blank of different diameter pipe, heating and holding (to ensure that the blank is burnt through), then pressing the blank after discharging from the furnace, putting the blank into the mould and pressing it with a press. 3. Shaping: Heating the diameter pipe again, and processing the diameter with press and brace until it meets the requirements. 4. End removal: Take the center of the diameter pipe as the reference to measure a certain distance from the two ends, and remove the surplus parts with gas cutting or plasma cutting gun. 5. Heat treatment: According to the heat treatment process, the tube with different diameters is put into the furnace for heat treatment. 6. Surface treatment: After heat treatment, the surface oxide scales of the pipe fittings are removed by sandblasting machine. 7. Mechanical properties testing: According to relevant standards, the mechanical properties of different-diameter tubes are tested to ensure that the mechanical properties of different-diameter tubes meet the standards. The testing items and sampling directions should meet the requirements of relevant standards or technical specifications. 8. Groove processing: mechanical end processing groove according to design confirmation drawings. 9. Appearance detection (1) There should be no cracks, over-burning, over-heating and other phenomena, and no hard spots on the surface of the pipe. (2) No obvious folds are allowed in the transition zone. (3) Welding repair is not allowed for any defect on the body of the pipe with different diameters. 10. Dimension Detection The company's relevant inspectors, according to the drawings and pipe fittings related standard requirements for dimensional testing, and meet their tolerance requirements. 11. Surface treatment (grinding): The inner and outer surface of the pipe should be smooth, without any damage to strength and appearance defects, such as scars, scratches, heavy skins, etc. When defects are found, they should be grinded. The thinning of the grinding area should be no less than 93.5% of the original wall thickness. The grinding area should be smooth and be cleared by staining agent or magnetic powder inspection. 12. Non-destructive Testing of Hot Pressed Variable Diameter Pipe After heat treatment, the qualified certificate holder of the company carries out radiographic inspection of the weld seam according to the requirements of the standard. The results should meet the requirements of NB/T47013.2-2015 II level. The magnetic powder or penetration test should be carried out on the body of the pipe. The test results should meet the requirements of NB/T47013.4-2015 or NB/T47013.5-2015 I level. 13. Acid pickling and passivation treatment Pickling and passivation of stainless steel pipe parts 14. Identification Mark with a spray-brush or low-stress impression, and clearly mark the contents required by the standard on the outer wall in sequence. 15. Storage and transportation of different diameter pipes In the course of transportation, the diameter pipe can not contact any part of the carriage to avoid bumping. |

- Telphone- 0317-6165555 6689999

- E-mail- 798758696@qq.com

- Address- Yanshan County Industrial Park, Cangzhou City, Hebei Province

- Telphone- 0317-6165555 6689999

- E-mail- 798758696@qq.com

- Address- Yanshan County Industrial Park, Cangzhou City, Hebei Province